Behind the scenes of innovation

Tested for uncompromised charging

Research and development

Hydrogen technologies

Electromobility laboratories center

IT charging systems

certification center

Power electronics in charging stations

Behind the scenes: How do we test our charging stations?

Have you ever wondered what happens before an EV charger reaches production? The journey takes years of research, development, and testing from concept to installation. At Ekoenergetyka, we put our prototypes through rigorous laboratory testing from climate testing through EMC testing to noise tests to ensure the highest quality, reliability, and compliance.

Learn moreExtreme conditions?

No problem!

Before going into production, every charger is tested

in climate chambers to simulate real-world conditions.

Temperature range:

-35°C

to

+55°C

Humidity resistance:

Up to

95% RH

Long-term durability test:

Heatdump test for

24 days

to replicate years of use

Our bestseller all-in-one Axon Easy is reliable in all weather conditions - from -35°C to +55°C. This makes it considered one of the best in its class, meeting the requirements of even the most demanding customers and locations.

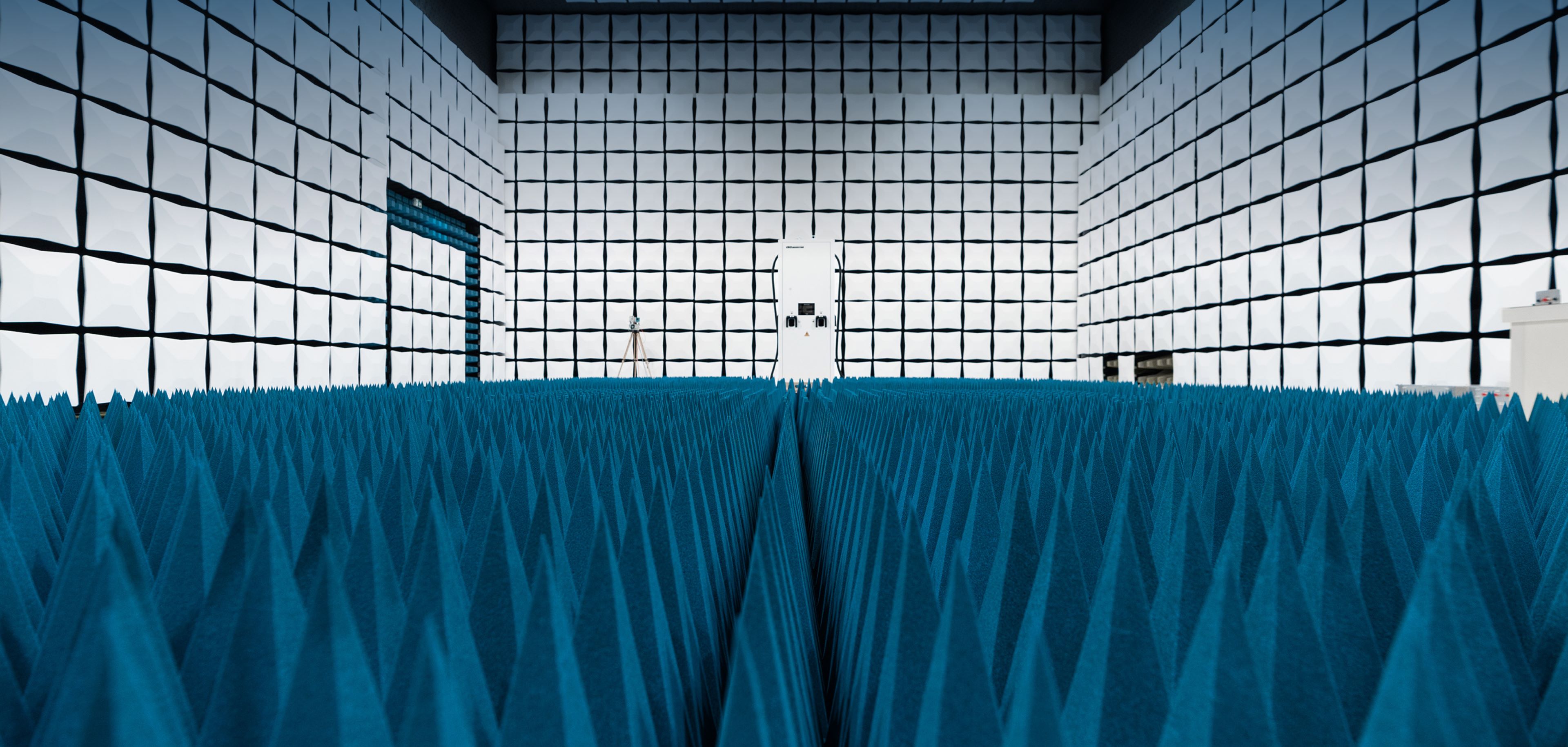

Let’s talkZero interference?

EMC testing confirmed

Our EMC chamber—one of Europe's most advanced,

ensures that our chargers operate without disrupting

other electronic systems.

Emission &

immunity testing

Ensuring stability in

high-electromagnetic

environments

High-power

testing

Up to 800 A, preventing

interference with

vehicle electronics

Compliance with

global EMC

regulations

This means Ekoenergetyka chargers integrate smoothly into urban and industrial infrastructures without causing signal disruptions.

Let’s talkAt Ekoenergetyka,

perfection is engineered

By conducting these advanced tests (and more),

we ensure that every charger we produce is:

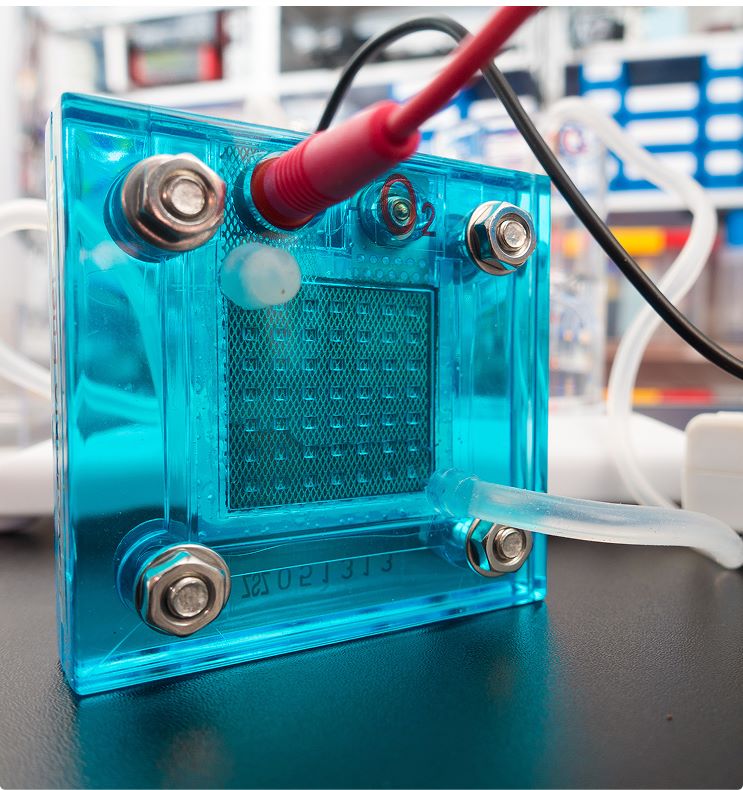

Hydrogen Technologies – Expanding the Possibilities of E-Mobility

While our core expertise lies in EV charging infrastructure, we are also exploring hydrogen’s role in complementing zero-emission transport.

Ekoenergetyka focuses on developing charging solutions for electric vehicles, but we also recognize the potential role of hydrogen in specific transport segments. As part of our R&D efforts, we established the Hydrogen Technology Research and Development Center for Transportation, dedicated to analyzing, testing, and developing hydrogen-based solutions. Our goal is to better understand this technology and its possible applications to support the advancement of sustainable mobility in Europe.

Let’s talkPower Electronics in Charging Stations – Innovations on a Global Scale

We develop cutting-edge power electronics solutions that set new standards in EV charging infrastructure.

Through our R&D initiatives, we design proprietary power electronics technologies tailored to the evolving needs of the e-mobility market. One of our key achievements is the development of an HPCVC (High Power Commercial Vehicle Charging) station with an output voltage of 1500 VDC and a charging current of up to 500 A. From the initial design phase, we focused on numerical modeling, energy properties, thermodynamics, electromagnetic compatibility (EMC), and noise emission analysis.

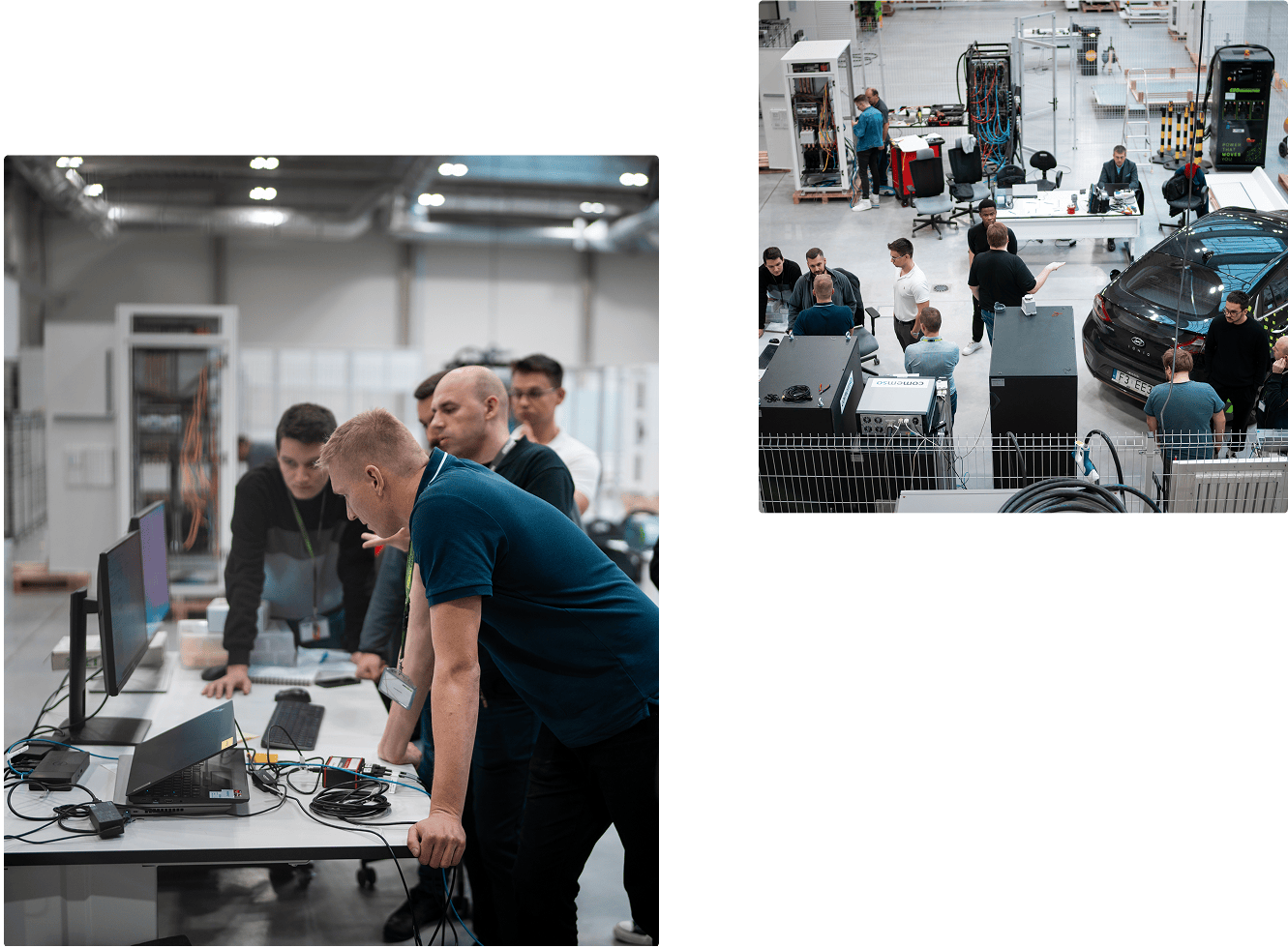

Let’s talkIT charging systems testing center

We develop and certify technologies that meet the highest international standards.

Ekoenergetyka operates its own IT Charging System Certification Center, where we implement R&D results to optimize the technological development process. By introducing smaller, in-process control stages, we continuously verify whether our charging stations comply with ISO 15118 and IEC 61851 standards. This approach allows us to make real-time adjustments to the charging station design, particularly in critical telecommunication infrastructure areas, ensuring full compliance with international standards and the highest quality of charging technology.

Let's talk