In the US and Canada, the EV charging market offers several DC stand-alone or all-in-one charger options, primarily dominated by 180kW and 400kW models. While stepped-down versions like 120kW, 240kW, and 320kW exist, the industry has largely standardized around the 180kW and 400kW packages. This variety presents both opportunities and challenges for the market.

Why is a 180kW DC fast charger preferred?

Avoiding overkill for most EVs today

While 400kW charging stations may seem appealing, they are often excessive for the current EV market. Most EVs cannot utilize such high power outputs due to their inherent charging limitations.

Today, a 180kW charger is highly practical and often optimal. Because most EVs are currently on a 400V architecture, a 180kW can charge most vehicles at their maximum sustainable capacity. A vehicle with a 400V peak charging capability will charge equally fast on a 180kW or 400kW charger, as the vehicle itself, not the charging station, becomes the limiting factor.

Some factors that level the playing ground for EV charging speed are:

- Electric vehicle max charging capabilities

- The Electric Vehicle Charge Curve

- Splitting of the chargers ports

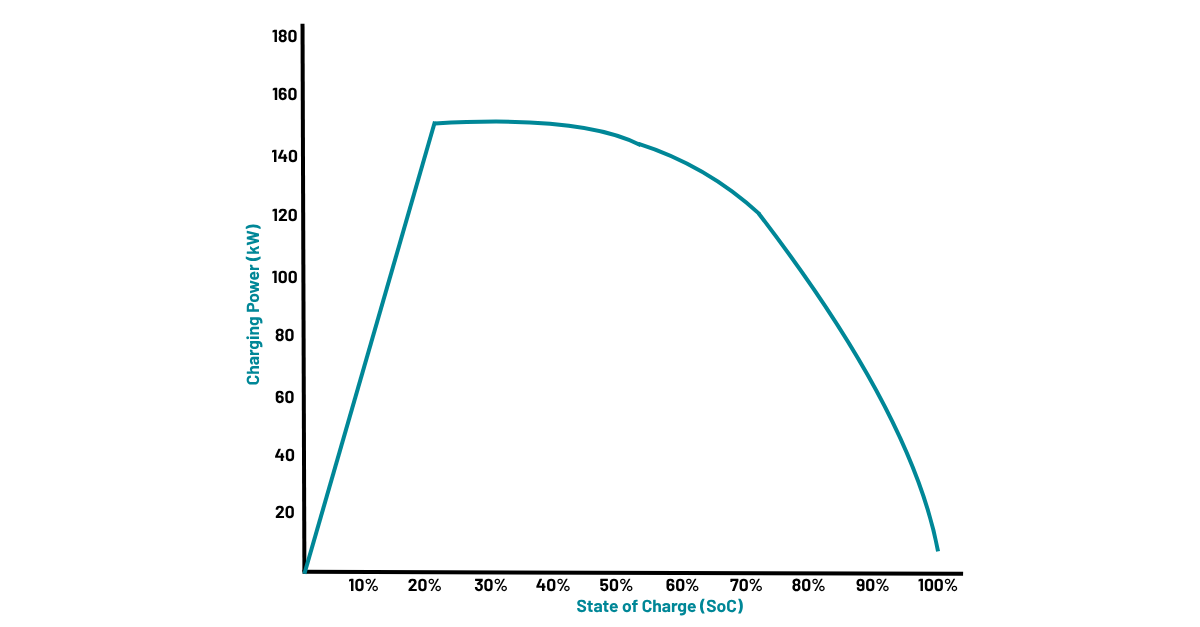

Average Estimated Charge Curve for 400V EV

Estimating the charge time for a typical EV

Charging a Tesla Model Y (Long Range) from 10% to 80% (52.5 kWh) takes about 22.5 minutes, whether using a 180kW or 400kW DC fast charger. This is because the car's charging speed is capped at 170kW (peak 170–250kW), with a realistic average of 130–150kW due to slowing after 50–60%.

The Model Y will charge in a similar timeframe whether it's connected to a 180kW or 400kW charger, owing to the battery's specific charging parameters.

Infrastructure Limitations

Using 400kW chargers when 180kW suffices creates infrastructure challenges. Higher power requires more robust grid connections, advanced cooling, and costlier components, increasing installation and operational expenses, which impact consumer charging prices. Prioritizing 180kW allows for efficient resource allocation, accelerating accessible and reliable charging network development for current EV drivers.

In comparison, a 180kW charger needs a 300A breaker, whereas a 400kW charger requires a 700A breaker.

Higher Charger Density

180kW chargers, half the cost of 400kW, allow CPOs to deploy more units. Each 180kW charger supports both CCS and NACS for maximum compatibility.

Increasing the density of 180kW chargers offers several advantages:

- Enhanced Simultaneous Charging

- Improved Load Management

- Optimized User Experience

- Higher Asset Utilization and ROI

Why is a 400kW DC fast charger preferred?

Future proofing for eventual faster turnaround time

Installing 400kW chargers today enables faster future charging for higher voltage batteries. This means quicker turnaround times, minimizing downtime for fleet operators and allowing CPOs to serve more customers.

Many US car brands are moving to higher voltage systems

These brands are anticipated to offer more 800V vehicles soon:

- Cadillac

- GM

- Volkswagen

- Audi

- Maserati

- Mercedes-Benz

- Hyundai

- Volvo

- Lucid

As electric commercial fleets grow, especially those with high-voltage vehicles, 400kW chargers will be essential for their larger battery packs. Fleet managers will particularly benefit.

Competitive differentiation for CPOs

Highlighting 400kW charging capabilities allows Charge Point Operators (CPOs) to present their sites as cutting-edge and distinct from competitors offering slower alternatives. Time-conscious drivers generally prefer the quicker charging option, even if their battery's actual charging speed doesn't fully utilize the faster charger.

The promise of the fastest available charging attracts customers and can command a premium for kWh sold. For fleet applications, the reduction in dwell times for load switches could also justify the investment.

More incentive eligibility

Certain state and federal programs may require or favor higher-power chargers for compliance or funding. Site owners could leverage incentives that might not be accessible for 180kW chargers. It's crucial to verify with local and federal programs.

Some rebate and incentive programs that favor higher power charging are:

- CALeVIP/Fast Charge California

- Golden State Priority Project

- NJ - EV Tourism Corridor Charging Program

Better at splitting charges

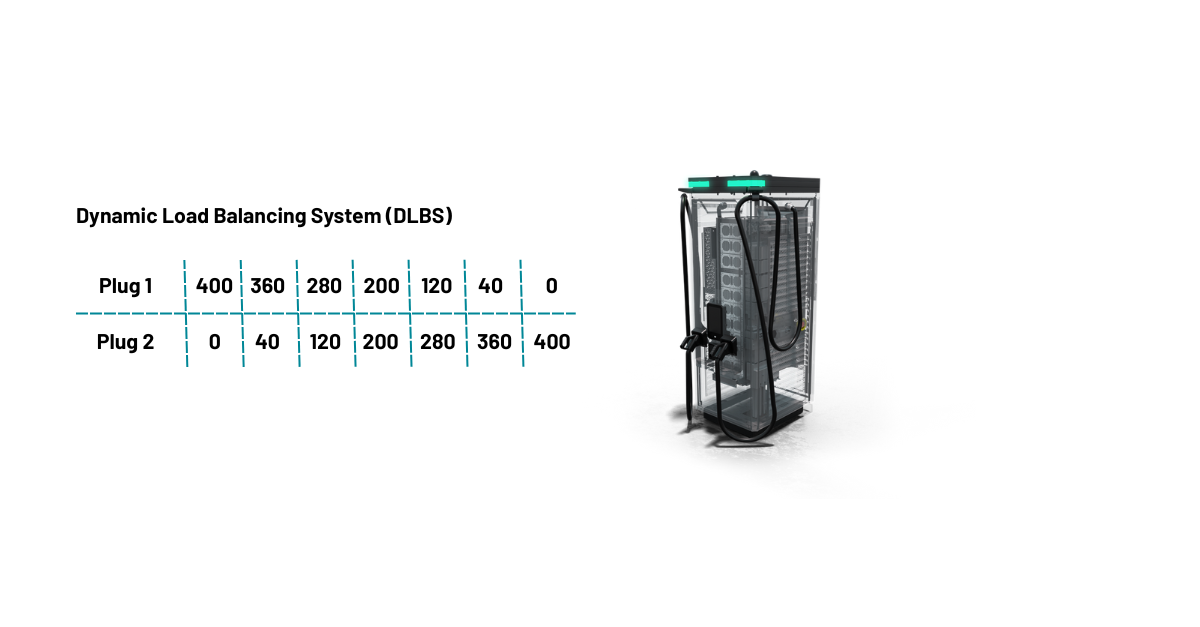

Many 400kW chargers are divided into 200kW segments, which is ideal for two vehicles with similar charging requirements. Some chargers further enhance this by incorporating a Dynamic Load Balancing System (DLBS).

What is a Dynamic Load Balancing System?

A dynamic load balancing system optimizes charging efficiency for multiple vehicles. It ensures each vehicle receives a minimum power supply, while intelligently distributing surplus power for quicker charging times. This real-time power distribution maximizes the charger's potential, depending on the battery's charge curve, and reduces operational expenses.

Brands such as Ekoenergetyka have developed 400kW all-in-one chargers that utilize dynamic load balancing, distributing power in 40-80kW increments. This enables vehicles requiring lower power to charge simultaneously with higher-power vehicles without hindering each other's charging speeds.

Which charger is better: spoiler alert…

Choosing between a 180kW and a 400kW charger depends entirely on an investor's specific goals.

Currently, the 180kW charger generally offers the most balanced solution, providing an optimal blend of cost-effectiveness, performance, and compatibility with existing infrastructure. While a 400kW charger can be seen as a future-oriented investment, it typically exceeds the immediate power demands of most current users and fleets. However, it is expected to become a highly practical choice in the future.

In many scenarios, the operational benefits do not justify the significantly larger capital expenditure required for a 400kW charger, even if there's a perceived value or specific use case.